With the rapid development of new energy automobile industry, new energy wiring harnesses get development opportunities. The difference between a high-voltage wire harness and a low-voltage wire harness is that the high-voltage terminal tends to generate heat due to the high current passing through the terminal. As a result, the mechanical strength of the terminal and the insulation performance of the wire harness are decreased, and the oxidation of the conductor further aggravates the heating.

High voltage terminal crimping needs to consider both the reliability of the crimp and the low temperature rise of the crimp.

High voltage terminals are commonly crimped

Crimping, resistance welding, high frequency welding

Crimping uses crimping equipment and dies to join wires and terminals together through a crimping process. High frequency welding is the use of high frequency welding machine to weld wire and terminal together. Resistance welding is the use of special resistance welding equipment to connect the wire and terminal together.

Advantage

Simple operation, convenient maintenance, low manufacturing cost, high operating efficiency, suitable for mass production.

Shortcomings

The wiring harnesses and terminals that require high current pass rate and low resistance after the connectors are connected cannot be met.

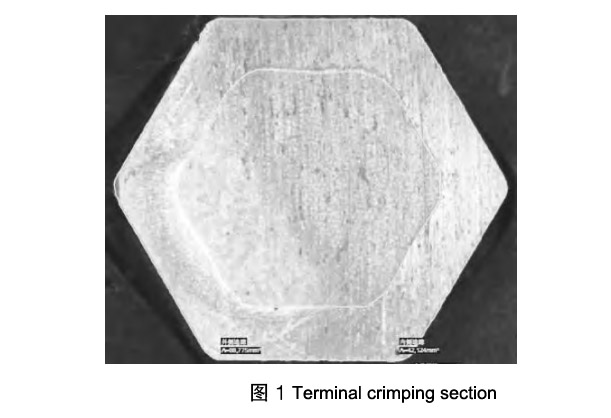

Figure 1 shows the common crimping modes of large square high voltage terminals, which are hexagonal closed terminals.

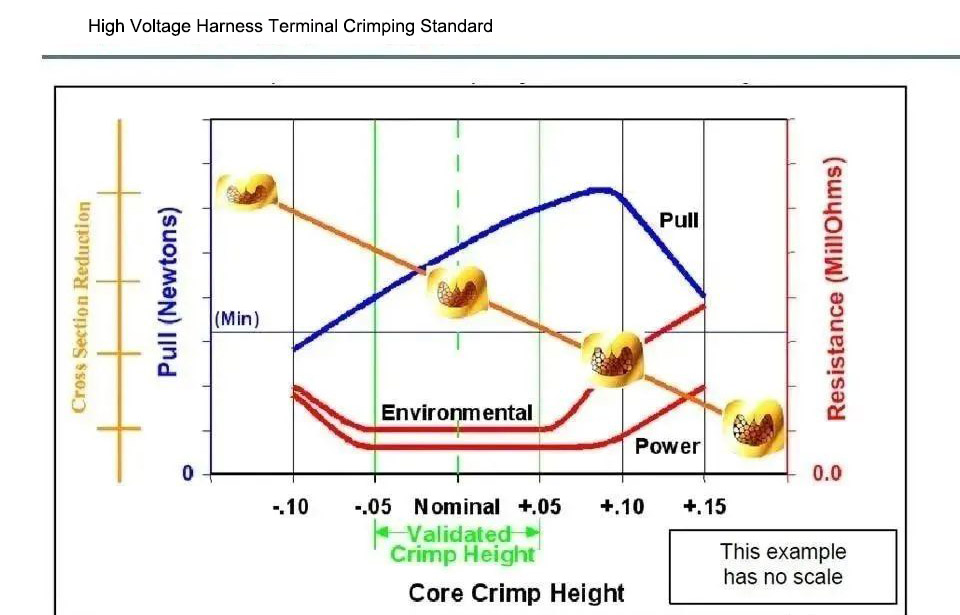

The advantages of ordinary crimping are obvious, but how to make ordinary crimping develop advantages and avoid disadvantages, as far as possible to reduce the resistance is particularly important. Reducing resistance means reducing heat, reducing product temperature rise, making product life and quality better.

Hazard of terminal heating

After the terminal is heated, it is easy to oxidize itself and the contact surface of the conductor of the wire, generating oxide film, so that the contact resistance increases, and the increasing speed increases exponentially with the increase of temperature, further increasing the terminal temperature rise speed, and serious fire will be caused. At the same time, the elastic element of the contact structure will be annealed, the contact pressure will be reduced, and the contact resistance will be increased further. In addition, the heating will make the wire insulation layer connected to the terminal aging brittle, resulting in a decline in insulation performance, there is the risk of leakage overheating caused by fire.

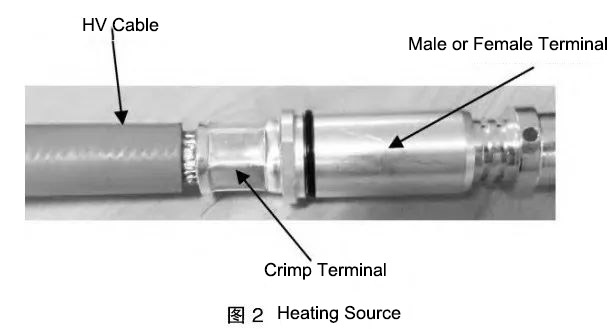

As shown in Figure 2, the high voltage wiring harness has three heat sources.

Terminal three heat source :

Conductor Conductor: The conductor itself has a resistance. The smaller the cross-sectional area, the higher the resistance. Resistance will cause heating.

Terminal compaction: insufficient compression ratio will make the conductor loose, resulting in large resistance, easy to heat. Excessive crimping is easy to cause small cross-sectional area, carrying flow is not enough to cause heating.

Male and female terminal contact: The terminal contact is not good, or the terminal contact surface oxidation leads to serious heating.

Method of reducing terminal temperature rise

Reduce contact resistance:

Use materials with low resistivity. The commonly used high-voltage terminals are H62, H65 copper, or high-conductivity copper. For products larger than 125 A, high-conductivity copper with low resistivity is recommended. Reduce the contact resistance of the conductor. Compact the terminal and conductor as much as possible to reduce the crimping resistance. Increase the cross-sectional area of the conductor, increase the cross-sectional area, and reduce the temperature rise of the conductor.

Increase the heat dissipation area of the conductor:

Adopt forced cooling, can use air cooling, water cooling and other measures. Reasonable arrangement of conductors, wiring harnesses with large current, as far as possible in the space easy to heat dissipation, conducive to natural heat dissipation.

Effect of crimping on temperature rise

Crimping, refer to QC/T 29106-2014 "Automotive Wiring harness Technical Conditions" 4.2.6 voltage drop test requirements and GB/T 20234.1-2015 "Connecting devices for conduction charging electric vehicles Part 1 General requirements for temperature rise test requirements for verification

According to the experimental data, the fluctuation of some resistance and temperature rise data is related to the coating and oxidation of terminals as well as the contact structure of terminals, so it is far from enough to reduce the temperature rise only from the consideration of crimping quality. It is necessary to pay attention to the daily storage of terminals against light, coating quality of terminals, terminal plug life, plug strength, contact area and other factors. For products with large temperature rise, it is recommended to use high-frequency welding, which makes copper melt and bond through friction heating at ultra-high frequency. This method has lower resistance, so it has better effect in controlling temperature rise.

If you know more about high voltage wiring harnesses or want to purchase high voltage wiring harnesses, please contact Aichie Tech Electronic Co., LTD:

AICHIE Tech Electronics Co.,Ltd

Email: sales03@aichie.com

Mobile/Whatsapp/WeChat: (86)18027502150

Skype: live:.cid.8643b3df38ff8b5