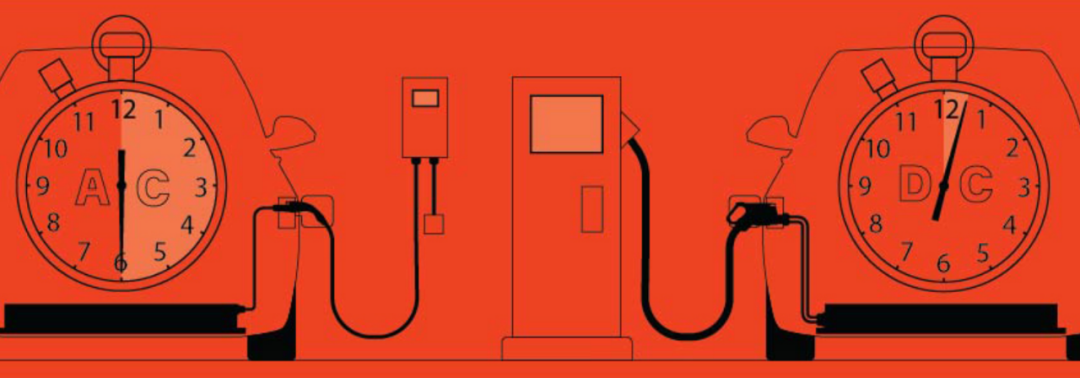

When consumers are looking to purchase an EV, the time it takes to charge an EV continues to influence their purchasing decision. Today, the fastest way to charge an electric vehicle is high-power direct current (DC) fast charging. DC fast charging, unlike AC charging, requires specific OEM considerations when designing critical components of the vehicle's electrical architecture, such as charging sockets.

The slower charging options (AC Level 1 and AC Level 2) use alternating current, which is how electricity is usually delivered from the grid and how it is delivered to homes. According to the SAE J1772 standard in North America, AC charging rates can vary from 12A to 80A, while elsewhere charging rates vary according to regional standards such as IEC 62196 or GB/T 20234. When EV owners charge their vehicles at home, they plug the EV charger into the vehicle's charging port, and the EV's on-board charger converts the AC power to DC to charge the battery.

DC fast charging is the most commonly used charging method at commercial public charging stations. These charging stations convert the alternating current from the grid to direct current, so when an owner charges an electric vehicle, the direct current flows directly to the battery. According to the J1772 standard, there are two levels of DC fast charging: DC Level 1 has a charging rate of up to 80A, and DC Level 2 (often referred to as Level 3 charging) has a rate of up to 500A.

The time difference between AC charging and DC fast charging is huge. AC Level 1 charging has a power output of up to 1.4 kW at 12A and 120VAC, while AC Level 2 charging can deliver up to 19.2 kW at 80A and 240V. In theory, it would take about five to six hours to top up the 100-kWh battery pack, even using the 19.2-kilowatt AC charging top power level. In comparison, using DC fast charging at 500A and 400VDC, the theoretically same 100kWh battery would take around 30 minutes to reach full capacity. With the advancement of battery technology, the upgrade of 800V architecture, and the improvement of charging infrastructure, the charging time will be further reduced.

Influencing factors

There are several factors that affect the speed of DC fast charging, such as the following:

Battery pack limitations:

Every EV battery has a specific acceptance rate, measured in kilowatts, that reflects how quickly it can store electrical energy. For example, if a DC fast charger is rated at 150kW, but the vehicle's battery can only accept 100kW, then it will definitely take longer to charge. A battery's acceptance rate can vary based on several factors, including battery chemistry, design, size, and age. Many OEMs are looking to upgrade their battery pack architectures from 400V to 800V to maximize acceptance and reduce charging times.

Temperature:

Extreme ambient temperatures, including high and low temperatures, can reduce charge rates or even render batteries unacceptable for charging at all.

Charging:

In general, EV battery acceptance is highest when the battery is at a low state of charge (SoC), and decreases as the battery approaches its maximum SoC. Most EVs follow a well-defined current curve, with charging slowing down significantly as the vehicle approaches full charge, especially once it reaches 80%, to reduce the risk of overcharging and damaging the battery.

Limitations of charging infrastructure:

Most DC fast charging stations on the market today have a maximum charging rate of around 200A to 300A. While the number of 500A DC fast charging stations is growing, they are expensive and complex to install.

Fever:

Due to its high current, DC fast charging generates heat throughout the EV charging system – from the EV charger to the inlet, from the high-voltage cables to the battery connections and the battery itself – and this heat must be managed. Standards such as J1772 and IEC 62196 stipulate that at the interface of the charging gun and the charging socket, the maximum operating temperature is limited to 90°C to ensure touch-safe conditions for consumers when operating the device. If the temperature approaches this limit, the charge rate will have to be reduced, so managing and monitoring this interface is key to charging performance.

The challenge for OEMs is to provide a charging interface flexible enough to accommodate AC charging and DC fast charging options in different regions, able to sense and dissipate heat, and employ a service-friendly design.

Tags :