Introduction

In the world of electronics and electrical systems, wire harness and cable assembly manufacturing plays a crucial role in ensuring reliable connectivity and efficient power distribution. Whether in automotive, aerospace, industrial machinery, or consumer electronics, these components are essential for transmitting signals and power safely.

This blog explores what is a cable assembly, the differences between wire harness and cable assembly, the benefits of custom molded cable assemblies, and how to choose the right cable assembly manufacturers for your needs.

What is a Cable Assembly?

A cable assembly is a group of wires or cables arranged into a single unit for transmitting electrical power or signals. These assemblies are often bound together with connectors, sleeves, or protective coverings to ensure durability and ease of installation.

Unlike a simple bundle of wires, a cable harness assembly is designed for specific applications, with precise lengths, shielding, and connectors to meet industry standards.

Key Features of Cable Assemblies:

- Protection: Shielding against EMI/RFI interference, moisture, and abrasion.

- Organization:Neat bundling of multiple wires for easier installation.

- Customization:Tailored lengths, colors, and connectors for specific applications.

Wire Harness vs. Cable Assembly

While the terms wire harness and cable assembly are sometimes used interchangeably, they serve different purposes:

Wire Harness:

- Typically consists of multiple wires bound together with sleeves or tape.

- Used for internal electrical connections within a device or machine.

- Less rugged than cable assemblies, often used in controlled environments.

Cable Assembly:

- More robust, with additional shielding and protective jackets.

- Designed for harsh environments (e.g., automotive, aerospace, industrial).

- Often includes molded connectors for secure connections.

For applications requiring high durability, a cable harness assembly with reinforced insulation and strain relief is preferred.

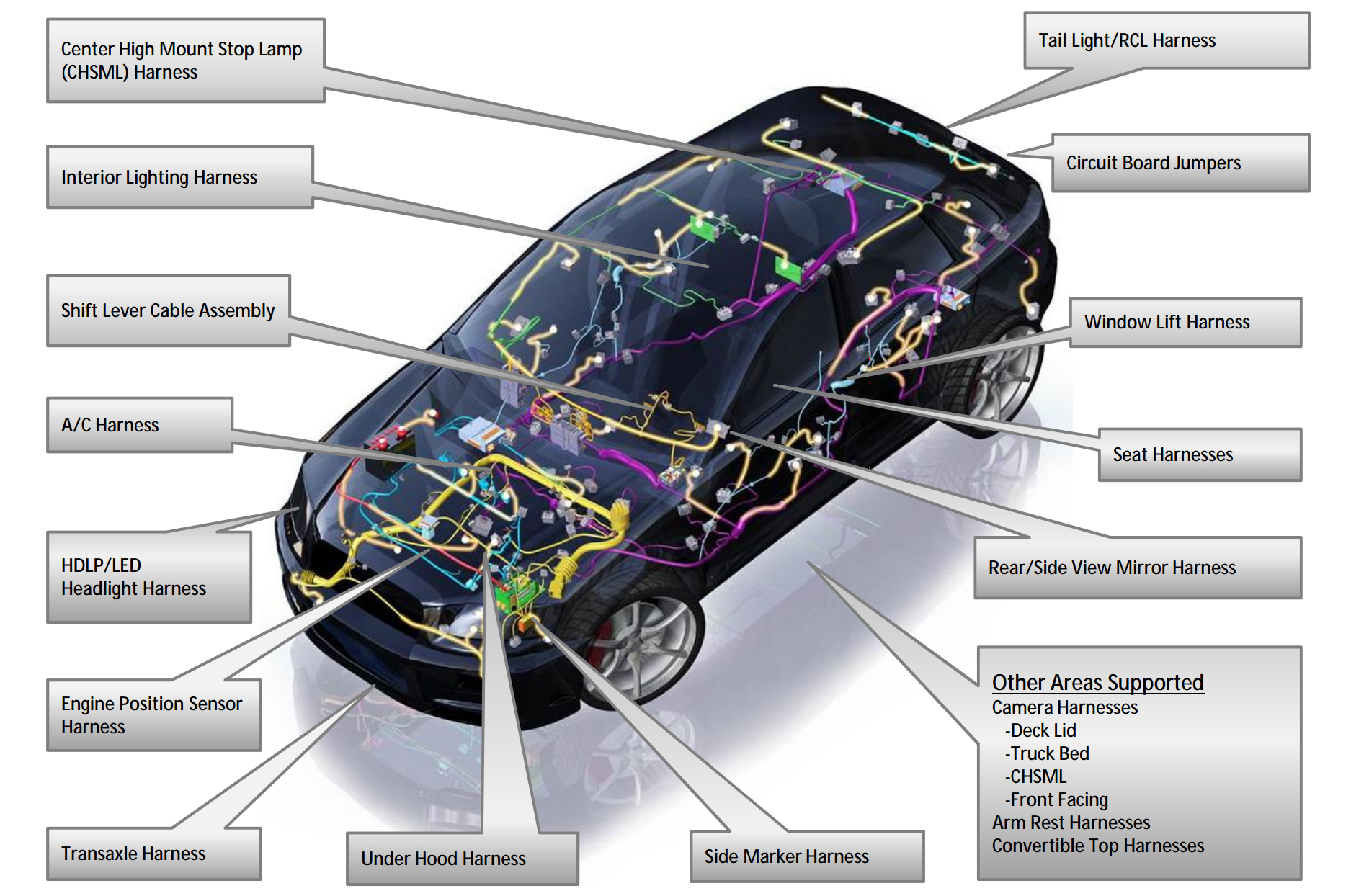

Applications of Wire Harness & Cable Assemblies

These components are used across various industries:

- Automotive: Engine control systems, infotainment wiring.

- Aerospace: Avionics, flight control systems.

- Medical Equipment: Patient monitoring devices, imaging systems.

- Industrial Machinery: Robotics, automation systems.

- Consumer Electronics: Appliances, computers, and smartphones.

Benefits of Custom Molded Cable Assemblies

For specialized applications, custom molded cable assemblies offer several advantages:

1. Precision Fit: Designed to exact specifications, ensuring compatibility.

2. Enhanced Durability: Overmolded connectors provide strain relief and protection.

3. Improved Performance: Reduced signal interference and better electrical conductivity.

4. Cost Efficiency: Minimizes the need for additional adapters or modifications.

Leading cable assembly manufacturers provide tailored solutions for industries requiring high-performance wiring systems.

Choosing the Right Cable Assembly Manufacturers

When selecting a supplier for wire harness and cable assembly, consider the following:

- Experience & Expertise: Look for manufacturers with industry-specific knowledge.

- Certifications: ISO, UL, and IPC standards ensure quality compliance.

- Customization Capabilities: Ability to produce custom molded cable assemblies.

- Testing & Quality Control: Ensures reliability and performance.

Conclusion

Wire harness and cable assembly manufacturing is a critical aspect of modern electronics, ensuring efficient and reliable connectivity. Whether you need a standard cable harness assembly or a specializedcustom molded cable assembly, choosing the right cable assembly manufacturers is key to achieving optimal performance.

By understanding what is a cable assembly and its applications, businesses can make informed decisions for their electrical connectivity needs.