The power source of a battery electric vehicle (BEV) is the high-voltage traction battery, and the electrical energy transmission throughout the vehicle is composed of power connection devices, cables, etc. BEVs contain high-voltage systems such as the main drive motor, braking, steering, electric heating, and air conditioning. For DC electrical equipment, the high-voltage energy transmission circuit primarily consists of cables, connectors, copper busbars, contactors, capacitors, etc. For AC electrical equipment, an IGBT module is added to the high-voltage circuit to convert DC high-voltage electrical energy into AC high-voltage electrical energy.

Composition of the Vehicle High-Voltage Circuit

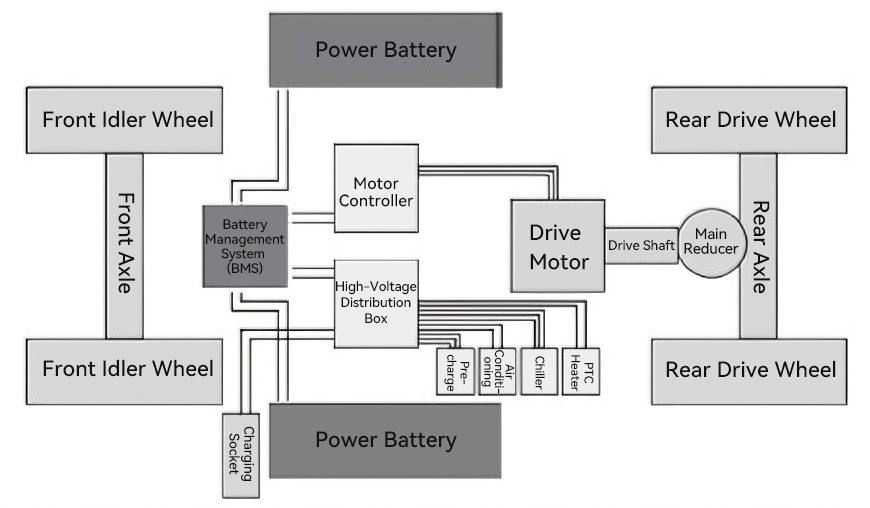

With the vigorous development of new energy vehicles, purely electric-driven vehicles are rapidly capturing an increasing market share. The energy transmission in BEVs is fundamentally different from that in traditional internal combustion engine vehicles. Based on the composition of the vehicle's high-voltage connection devices, a simplified schematic diagram of the vehicle's high-voltage circuit is as follows:

To ensure high-voltage power transmission, convenient plugging/unplugging, and precise control in BEVs, products such as high-voltage cables, quick-connect connectors, and high-voltage contactors are widely used in the electric vehicle industry.

High-Voltage Circuit Components

High-Voltage Cables

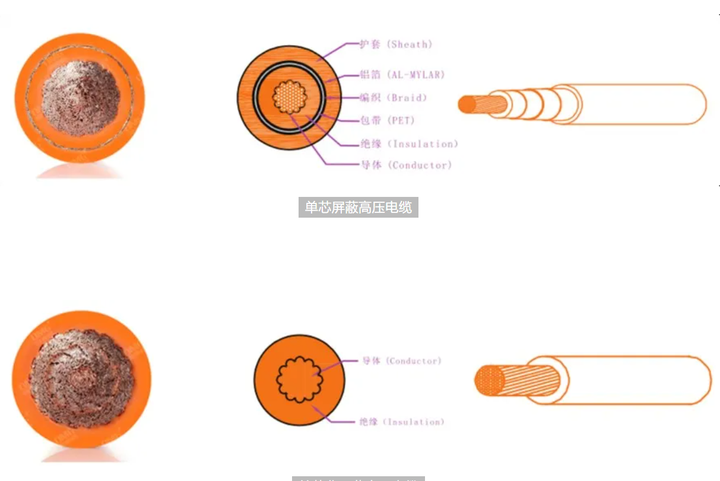

High-voltage cables are primarily responsible for transmitting electrical energy between electrical components. Currently, automotive high-voltage cables mainly comply with the QC/T 1037 standard. A diagram of a single-core shielded cable is as follows:

By Voltage Rating: Mainly AC 600V/DC 900V and AC 1000V/DC 1500V specifications. For the same specification, a higher voltage rating generally corresponds to a larger cable outer diameter.

By Shielding: Mainly shielded and unshielded cables. Shielded cables can improve the vehicle's EMC performance.

By Application Specification: Mainly single-core and multi-core cables. Single-core cables are primarily used for high-current transmission in main circuits, while multi-core cables are often used for current transmission to auxiliary components.

By Cable Material: Mainly cross-linked polyethylene (XLPE) cables and silicone rubber cables, etc. XLPE cables are relatively harder compared to silicone rubber cables. Silicone rubber cables have a smaller bending radius, making them suitable for cable routing in compact spaces.

Classifications based on temperature and current-carrying capacity are more detailed. Current cable application primarily involves selection and design based on voltage rating, current-carrying capacity, operating temperature, connector model, and installation space. There are numerous high-voltage wiring harness manufacturers, such as Xin Hong Ye and Hong Ji Huan Dian.

High-Voltage Connectors

These are mainly responsible for connecting electrical components to cables, and are also used in some cases for connecting cables to each other.

Connectors can be categorized by usage into quick-connect connectors and standard connectors. Standard connectors mainly use copper terminals with bolt connections and have lower costs. Quick-connect connectors are widely used due to their convenience and ease of plugging/unplugging for maintenance.

Most high-voltage connectors have an Ingress Protection (IP) rating of IP67 or higher, meeting the installation requirements for various locations.

High-voltage connector materials are mainly metal and plastic. Most connectors support internal connection of the shielding layer and feature a High Voltage Interlock Loop (HVIL) function, meeting the requirements for high-voltage cable grounding and insertion detection. There are many connector manufacturers in the industry, such as TE Connectivity, Amphenol, AVIC Jonhon, Recodeal, and Yonggui.

Busbars

Busbars are primarily used inside components like the battery and its management system, motor controller, and auxiliary drive controller. Due to the regular internal layout of these components, convenient installation and fixation, and less stringent protection requirements, high-voltage current inside electrical components is mainly connected via busbars.

They can be distinguished by material into copper busbars and aluminum busbars, etc. Their bending characteristics and hardness vary depending on the material, allowing for custom design based on specific application scenarios.

Contactors

Contactors are primarily responsible for switching the vehicle's high-voltage circuit ON/OFF. Their working principle is similar to low-voltage relays: a low-voltage current controls the contactor coil to generate a magnetic field, which closes the two high-voltage contacts, thereby energizing the vehicle's high-voltage circuit. Since high-voltage contactors switch the high-voltage circuit, issues like arcing and contact welding may occur during operation. Therefore, high-voltage contactors have strict requirements regarding contact material, actuation time, working medium, operational temperature rise, etc. Product varieties are also diverse.

Current industry manufacturers of high-voltage contactors include: TE Connectivity, Siemens, LG, SCII, Hongfa, and Guoli.

Fuses

Categorized primarily by placement into quick-disconnect fuses and standard high-voltage fuses. The quick-disconnect fuse, also called a Manual Service Disconnect (MSD), is mainly installed outside the battery pack or Battery Management System enclosure, serving both circuit protection and power disconnect functions for maintenance.

Standard high-voltage fuses are mainly installed inside enclosures like the motor controller, responsible for high-voltage circuit protection functions. Current industry manufacturers of high-voltage fuses include: Chint, Delphi, Zhongrong, and ETA.

Sensors

Hall effect current sensors and shunts are used for current measurement in the high-voltage circuit. Shunts are widely used in the new energy vehicle industry due to their high measurement accuracy and small errors.

Capacitors / Diodes / Resistors

Combinations of capacitors, resistors, etc., form buffer/snubber circuits within the vehicle's high-voltage circuit, used for power-up buffering and power-down self-discharging in controllers.

Conclusion

Based on the development trends in the new energy industry, future new energy vehicle models driven by electric power will occupy a major share of the automotive market. As the market continuously pursues higher safety and intelligent control of vehicle high-voltage circuits, the composition of electrical connections will become more diversified, and product performance will continue to improve accordingly.

Aichie Tech is a professional provider of connectivity solutions, focusing on the design and manufacturing of high-quality connectors, wires, and cable assemblies. It creates value for customers through technological innovation and exceptional quality, driving industry advancement.

Email: sales03@aichie.com

Tel/Whatsapp/WeChat: +86 18027502150

Contact: Aichie Team