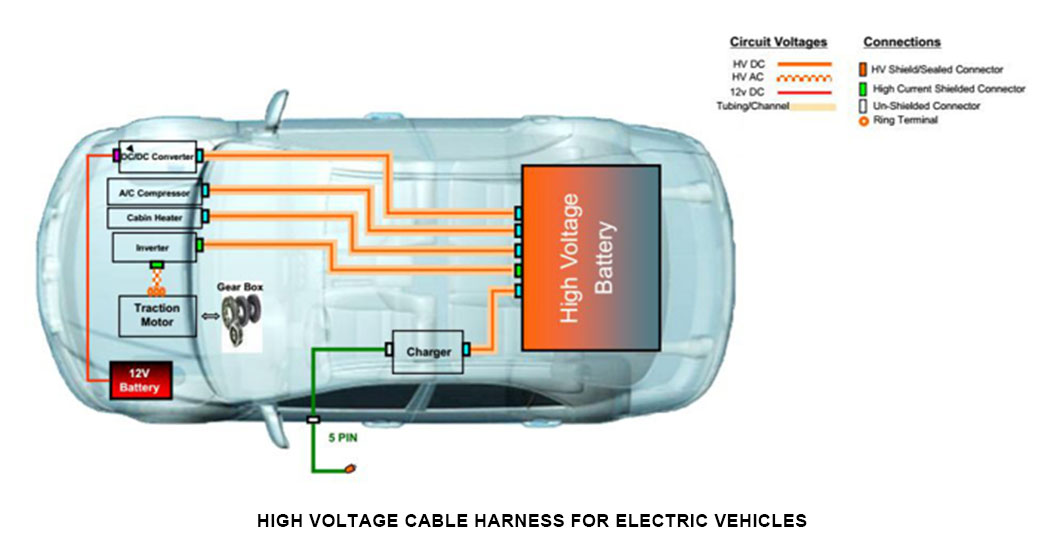

The application scenarios of new energy cables are mainly car interior, charging gun/charging pile and car charging, and the high-voltage wiring harness in the car is mainly to provide high-voltage and strong electric power supply for new energy vehicles, which is a high safety part in new energy vehicles, with large voltage/large current, large diameter wire number and other characteristics. This also makes the design of high-voltage wiring harnesses in new energy vehicles face a lot of challenges. Today, we will learn the wiring harness design and wire requirements of new energy vehicles.

wire outer protection

(2) seal match with high pressure connector, using wire seals, heat shrink tubes, Pass-thru seals, rubber parts and other ways to seal for water and dust (IP67, IP69K). The wire is required to have good roundness, dimensional stability and aging performance.

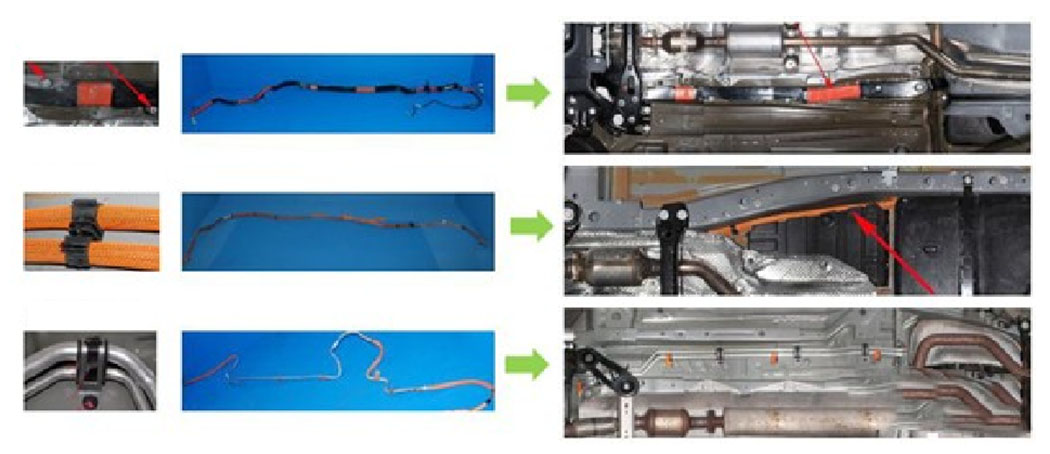

2. The high-voltage wiring harness layout in the cabling car has the following requirements: (1) Under static load, the minimum turning radius is 4 times the outer diameter of the conductor; (2) Under dynamic load, the minimum turning radius is 8 times the outer diameter of the conductor; (3) The minimum distance between high and low voltage wires is not less than 100mm; (4) The distance between the outlet end of the high voltage connector and the first fixed point is not more than 100mm, and the distance between the adjacent fixed points is generally not more than 150~200mm; (5) The high-voltage wiring harness is arranged under the car as far as possible; (6) Wire selection toughness wire such as silicone rubber wire, flexible cross-linked polyolefin wire.3. Shielding because of the electromagnetic field interference caused by high voltage and large AC of new energy vehicles, as well as the electromagnetic interference caused by the rapid on-off of electrical components, taking into account the electromagnetic interference factors, the entire high voltage system is fully covered by the shielding layer. Then the high voltage wire harness shielding electromagnetic interference measures are: (1) the selection of shielding wire electric vehicle ultra-high current and voltage, operation will produce a large electromagnetic induction phenomenon, if not a good solution to the electromagnetic shielding problem, is bound to affect the performance of automotive electronic equipment, so choose shielding wire as electric vehicle high voltage wire for electromagnetic shielding is a good choice. The shield wire is braided by multiple strands of tinned annealed copper wire. The thin copper wire can maintain the flexibility of the design and has a coverage rate of more than 90%. Reasonable insulation and sheath stripping force should be controlled to meet the requirements of wire stripping processing. (2)Bundle Shielding is the overall shielding, and wire is unshielding, which is mostly used by Japanese Oems at present. Bundle Shielding is the protection of wire bundles from electromagnetic interference when a light braided metal shielding is used as a shielding component. Aluminum tube Shielding is also a Bundle Shielding, and the conductor is non-shielding, which is mostly used by Japanese and American Oems. Figure aluminum tube shielding example 4. Weight For new energy vehicles, lightweight is very important for the improvement of driving range. Then the weight of the wire harness can be started on the material selection, and the conductor material can be a new conductor conductor, such as a new aluminum conductor; The insulation material can be selected with low density material and thin wall processing. 5. Cost At present, the high-voltage wire in the car is mainly imported, the wire threshold is high, the output of mass production models in the early stage is less, new energy vehicles are facing greater cost pressure, and more domestic resources need to be developed. 6. Environmental protection high-voltage wiring harness in the car needs to use low-volatile, low-VOC, low-odor materials.