First, automotive wiring harness industry development overview

The superposition of positive factors on both sides of supply and demand has promoted the steady growth of the automotive wiring harness market

Automotive wiring harness is the key carrier of energy transmission and signal transmission, and is an indispensable system-level component in the vehicle. Under the general trend of electric intelligence, automotive wiring harnesses have benefited from the superposition of positive factors on both sides of supply and demand in recent years, ushering in a golden period of stable growth.

On the demand side, the consumer market's demand for advanced automotive functions is growing, such as safe driving has spawned the demand for active safety systems such as automatic emergency braking, blind spot detection, and front collision warning systems, and comfortable driving has spawned the demand for additional driving functions such as voice recognition systems, environmental lighting systems, and heated seats. The realization of the above functional requirements need to rely on the operation of electronic components, electronic components need wiring harness to ensure the transmission of signals, data and electrical energy, which constitutes an important driving force for the rapid development of the automotive wiring harness industry.

On the supply side, the "new four modernizations" of automobiles (referring to electrification, networking, intelligence, and sharing) trend has led the development direction of the industry, the automotive electronic and electrical functions continue to increase, the electronic and electrical architecture continues to iterative, and the rapid development of the industrial supply side is expected to release the development space of automotive wiring harnesses.

There are differences in the development trend of automotive wiring harness market segments

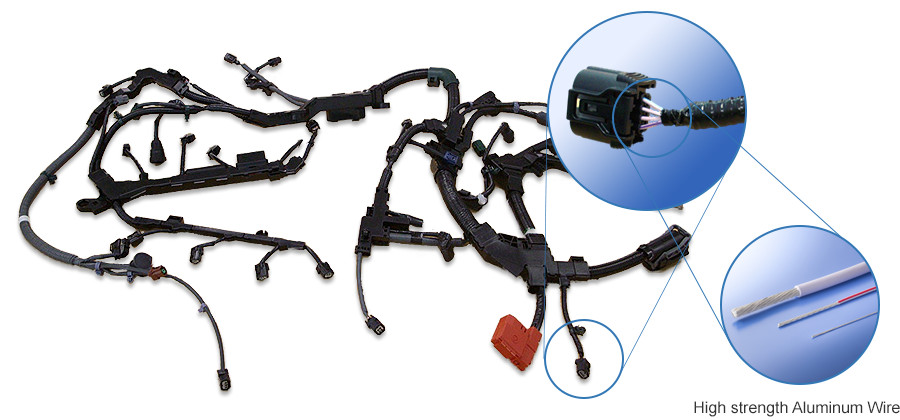

Thanks to the extensive application in fuel vehicles for many years, the low-voltage wiring harness market has developed into a relatively stable stock market. Low voltage wiring harness products are rich and mainly customized, need to carry out different wiring design according to different models and different parts of the car, superimposed wire texture is soft.

High voltage cable assembly is a pure incremental market spawned by the trend of electrification, with high voltage/high current, large wire diameter and other characteristics, determining the actual production and application process is faced with wiring, shielding, cost, safety and other challenges, in the raw material, production process, product design, performance levels and other aspects of the low voltage wire harness put forward higher requirements.

The industry concentration is high, and the domestic substitution process is accelerating

The development of the automotive wiring harness industry is highly dependent on the automotive industry, and most brand Oems have mature and stable automotive supporting systems. For a long time, high standards for parts have made the cooperation between wiring harness suppliers and Oems relatively stable. At present, the global wiring harness market is mainly dominated by Japan's Yazaki, Sumitomo Electric, Europe and the United States, Leni, Ambof, Lear and other manufacturers, forming an oligarchic competition pattern. In 2021, the combined market share of the top three companies in the global automotive wiring harness industry is 71%, and the combined market share of the top five companies is 82%, and the industry concentration is high.

Thanks to the improvement of synchronous development and independent research and development capabilities, superimposed cost advantages and localized service advantages, China's local wiring harness enterprises have gradually entered the supporting system of domestic and foreign automobile manufacturers, especially in the new energy vehicle wiring harness market, which has formed a relatively obvious domestic alternative breakthrough.

In recent years, local wiring harness suppliers, relying on a good supporting relationship with independent new energy manufacturers, have taken the lead in entering its supply system to achieve a first-mover advantage, and some high-quality suppliers have successfully achieved a technological breakthrough in the design and development of high-voltage assembly wiring harness, and have also formed a greater advantage in the price and gross profit of wiring harness. Relying on the rapid development of local new energy vehicle brands and quickly seize market share, so as to promote the localization of automotive wiring harness replacement into the accelerated stage.

Second, automotive wiring harness industry market size

The global automotive wiring harness industry market is growing steadily

Automotive wiring harness is the main body of the automotive circuit network, the central control components and automotive control units, electrical and electronic execution units, electrical components organically connected together to form a complete automotive electrical control system. Automotive wiring harness products are customized products, different vehicle manufacturers and different models have different design schemes and quality standards. At the same time, compared with fuel vehicles, the circuit system of new energy vehicles is more complex, which not only increases the performance requirements for wiring harnesses and connectors, but also increases the demand.

Under the background of the vigorous development of new energy vehicles in the world, major automobile manufacturers continue to increase the investment in new energy vehicles, the output of new energy vehicles in the world is growing steadily, and the output of new energy vehicles in China is increasing most rapidly. According to the analysis of QY Research, the global automotive wiring harness market size is approximately 357.4 billion yuan in 2022 and is expected to reach 574.4 billion yuan in 2029, with a compound annual growth rate (CAGR) of 6.6% during 2023-2029.

China's automotive wiring harness industry has a broad development space

China as the world's largest automobile producer, with the steady rise of China's automobile production and sales in recent years, China's automotive wiring harness market scale is also growing steadily, according to the "China Automotive high voltage wiring harness industry development trend research and investment prospects Analysis Report (2023-2030)" data, From 2016 to 2022, the total market size of China's automotive wiring harness increased from 67.05 billion yuan to 81.46 billion yuan.

Third, the development trend of automotive wiring harness industry

To high voltage transmission, high frequency high-speed transmission direction

In recent years, with the popularity of high-voltage electric platforms derived from vehicle electrification, and the application of a series of functional modules such as intelligent cockpit, vehicle networking, and intelligent driving spawned by intelligence, automotive wiring harnesses have generated strong iterative demands in terms of energy transmission power and signal transmission rate. Only relying on the low-voltage wiring harness widely used in the original fuel vehicle system can not help the realization of all electrical functions of the vehicle.

In terms of energy transmission, on the basis of low-voltage wiring harnesses, the structural design and manufacturing process of key components such as connectors and cables are greatly adjusted to improve the ability of high-power power transmission; In terms of signal transmission, through the optimization of the automobile bus topology and the development of special components such as superimposed high-speed data connectors, high-frequency high-speed transmission is realized.

To the direction of lightweight development

In the context of increasingly stringent global environmental standards, in order to reduce fuel consumption of fuel vehicles and improve the endurance of new energy vehicles, vehicle manufacturers are vigorously promoting lightweight vehicle production. According to the results of the CAAC energy-saving economic and technical analysis, a 10% reduction in the weight of fuel vehicles can reduce energy consumption by 5%-8%, while a 10% reduction in the weight of new energy vehicles can increase the range by 5%-10%, which can save 15%-20% of the battery cost and 20% of the daily loss cost.

Because the automotive wiring harness is mostly copper alloy wire, accounting for about 5% of the weight of the vehicle, the application of fuel vehicles is second only to the engine and chassis of the third heavy components, affected by this, the lightweight of automotive wiring harness has become the current industry key breakthrough field. In the future, with the increase of vehicle lightweight demand, wiring harness companies with deep technical reserves and mature lightweight solutions are expected to stand out in a new wave of development and establish a full competitive advantage.

Automotive wiring harness production to the direction of automation

Due to the complex wiring structure of the car, superimposed intelligent manufacturing has not yet popularized the whole process of wire harness production, so the production and assembly are highly dependent on the manual, which restricts the expansion of production capacity of manufacturers to a certain extent. At present, most automotive wiring harness manufacturers can rely on some advanced equipment to complete the wiring, crimping, pre-assembly links, but the latter process due to different types of product requirements, process standards, operating processes are different, the key assembly process still needs a lot of manual investment.

In the future, with the development of automotive wiring harnesses toward integration, automated production is expected to run through the whole process of design, production, logistics, management and so on, and continue to improve the level of automation by seeking the standardized part of customization to fully release the capacity potential of production enterprises.

Fourth, automotive wiring harness industry technical level, technical characteristics

The technical indicators of automotive wiring harness mainly include mechanical, electrical and environmental resistance characteristics. Mechanical characteristics mainly refer to the installation size, inserting and pulling force, mechanical impact and vibration and other technical requirements; Electrical characteristics mainly refer to circuit current carrying, signal transmission, electromagnetic interference, circuit protection, etc. Environmental resistance refers to the requirements of high and low temperature resistance, wear resistance, corrosion resistance, noise resistance and so on.

Automotive wiring harness is mainly used to connect the car battery, distribution box, actuator, controller, sensor and other components, to provide electrical energy and signal transmission for the vehicle electrical and electronic components, and to provide basic connection for the control loop, so that it can achieve all electrical functions. Electrical safety and signal accuracy require extremely high stability of the wiring harness connection, ensuring that the line does not produce overload, short circuit, open circuit, voltage fluctuations, and signal transmission attenuation.

In the design and manufacture of automobile wiring harness, in addition to ensuring its safety and reliability, stable signal transmission, and accurate electrical function control, it is also required that the design scheme consider reasonable wire diameter and materials, combined with the optimal installation design, so that the wiring harness occupies a small space, reduces its own weight and optimizes the cost of the wiring harness under the premise of ensuring various performance.

At present, in the field of high-end models, domestic wiring harness enterprises compared with foreign mature enterprises, there is still a certain gap, independent research and development, technological innovation capabilities need to be further improved. However, with the accumulation of independent development and supporting experience of China's automotive wiring harness industry for many years, product quality is more reliable, service level is more perfect, and a small number of large-scale wiring harness enterprises with synchronous development and design capabilities have been cultivated in the industry.