The EV battery connector has made further progress

Electric vehicle batteries are being improved, and the new interconnected products that support them have been optimized to manage the entire vehicle's high-voltage power flow with extremely high safety and efficiency.

Range anxiety - the fear that the battery of an electric vehicle will run out of power and leave you stranded by the roadside - has long been one of the main obstacles to the adoption of electric vehicles. However, with the expansion of charging infrastructure and the improvement of battery technology, this obstacle has begun to diminish. The electric vehicle database sets the average EV range at 331 kilometers (205 miles), with the top-ranked model reaching 434 kilometers (269 miles). This makes commuting and errands within easy reach, especially for homeowners who plug in electricity at home. Take a look at the evolution of the Chevrolet Bolt battery series. In 2017, the original battery of the Bolt was a 60 kWh battery pack, with an EPA range of 238 miles. Then there was the battery recall, which affected the models from 2017 to 2019. The car manufacturer has increased the vehicle's range by 13% through its 2022 66 kWh battery pack replacement solution. In the high-end segment, Tesla is collaborating with Panasonic on a new high-density battery project, which will increase its driving range by 20%. The Model S can currently travel 585 kilometers (263 miles) per charge.

Meanwhile, the charging infrastructure for electric vehicles is also expanding rapidly worldwide. Europe plans to add at least one fast charging station every 60 kilometers by 2025. In May 2022 alone, China built 87,000 public charging stations. In the United States, California leads with over 14,627 public charging stations, but even the sparsely populated state of North Dakota recently announced a plan to add one charging station every 50 miles along the two interstate highways that run through the state.

Major developments in electric vehicle battery pack technology include the use of new battery chemicals such as lithium tungsten, zinc manganese oxide, organosilicon electrolyte, gold nanowire gel electrolyte and hydrogen. Researchers from automakers and original equipment manufacturers of batteries and battery packs are expanding the ability of batteries to store more energy, charge faster and operate at lower temperatures. By improving the cables and connectors, these battery compositions are supported throughout the electric drive system. These improvements reduce the size of the component structure and the cables, enhance thermal management, and enable high-voltage currents to pass through the system more quickly. TE Connectivity estimates that up to 40% of the total bill of materials for new EVs can be attributed to the contents of their battery packs. Even if performance improves, the cost of batteries is still decreasing.

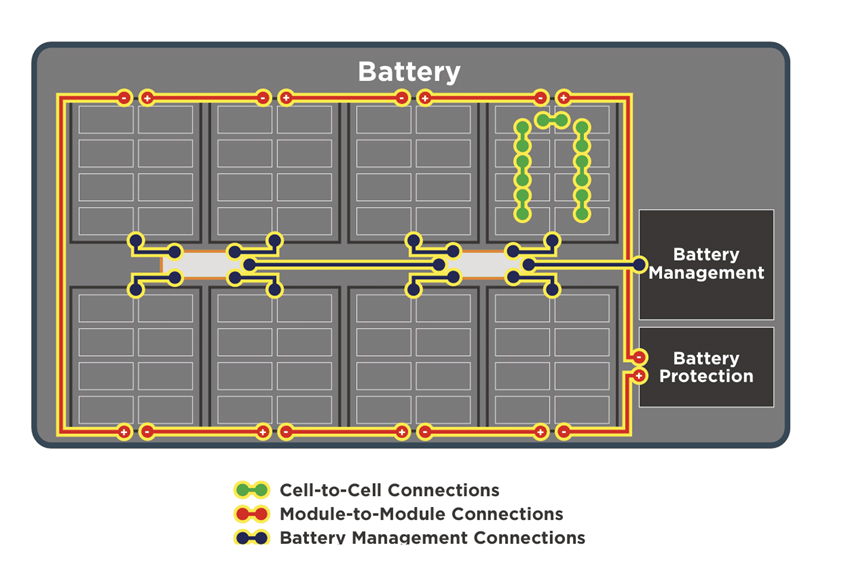

To achieve fast charging, we need to be capable of carrying a current of over 500 amperes within the charging cycle. At present, we limit it to 200 amperes. All components in the system, from the charging system to the entry point, and then to the high-voltage connectors and battery cells, need to be capable of handling high-power charging currents. One approach is to thermally manage the entire system. Therefore, this can be achieved through active cooling systems, larger cable sizes, low-resistance connectors, high-voltage connectors, and other means. "Each component in the system must be properly balanced and thermally managed," said e-Mobility, senior R&D product development engineer at TE Connectivity, noting that connectors directly affect the system performance terms in EV battery systems. Battery connectors must balance mechanical, electrical and thermal performance to maximize system performance. Oems and battery pack manufacturers need thin connectors with low contact resistance at all contact points to reduce power loss and heat.

During high-power direct current (DC) charging cycles, the main battery connection needs to carry a continuous current of up to 600 amperes within a few minutes, and the peak level is significantly higher during hard acceleration. In addition, the battery needs to operate reliably for over 180,000 miles (or approximately 10 years) at temperatures ranging from -40 °C to +75 °C, and the connection needs to operate at +150 °C or higher to accommodate higher load conditions.

This means that the interconnections must be made of heat-resistant and sturdy materials that can withstand high-temperature fluctuations for a long time. Both the charging cycle and operating conditions exert pressure on the components. Every part of the system must achieve the maximum degree of lightweight, high performance and high reliability. Even elements such as solder paste play a role in maintaining the integrity of the EV battery management system.

Shielding is another key consideration. High-density automotive environments are busy processing electronic signals from lighting, autonomous driving, safety, communication/infotainment, and powertrain systems. EV batteries and battery management systems - the "brain" of EV battery systems - must be protected from electromagnetic interference. The board-to-board connectors used between battery packs and control, communication and diagnostic systems must shield interference so that each system can operate as efficiently as possible.

High-power charging is really exciting. In addition to the updated battery technology, high-power charging will enable electric vehicles to travel long distances just as we are accustomed to in internal combustion engine vehicles. For instance, if your battery is running low and the charging current at the HPC station is 500A and 1,000V, you can get approximately 80% of the battery in three to five minutes, depending on your battery capacity, charging status, and whether your vehicle can handle this level of charging. Vince Carioti, director of electric vehicles at Allied Electronics & Automation North America, a supplier of electric vehicle products for Phoenix Electric, said.

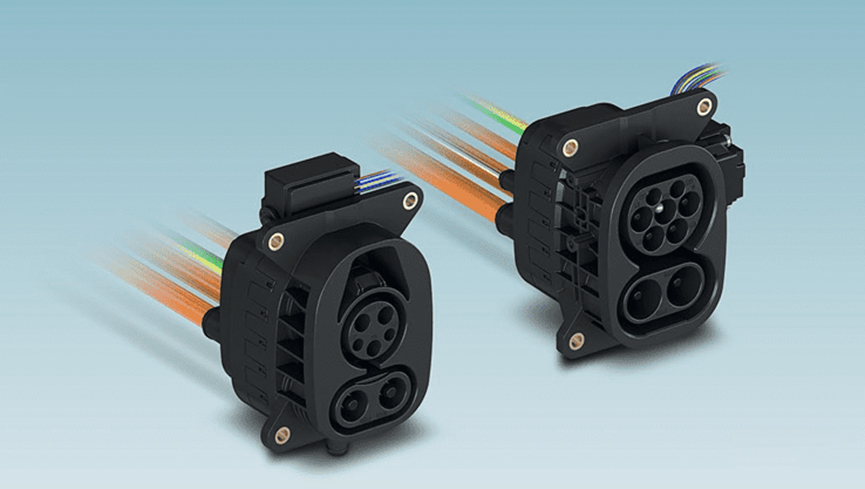

In addition to the CHARX high-power charging system (as shown at the entry in the above picture), Phoenix Contact also provides high-performance connectors for DC charging of large replaceable battery cells (as shown in the picture below). These connectors can handle currents up to 400, voltages up to 750 V DC, and more than 10,000 insertion/extraction cycles.

Another way to charge quickly is to replace the used battery with a fully charged one. This strategy is being widely implemented in China. Battery replacement stations promoted by the automaker Nio can install a new battery pack within three minutes. In other markets, replacement battery cells are used in multi-functional and working vehicles, such as forklifts, transport vehicles and buses. However, most electric vehicle charging is still carried out through charging connections embedded in the familiar handheld form. Electric vehicle charging connectors provide car owners with a "refueling experience" at charging stations.

With the accelerated adoption of electric vehicles, we will witness improvements in electric vehicle batteries and a decline in their prices. Interconnection technologies that help transfer energy into and through these systems will support these developments and the transition to electric vehicles.