In 2020, China's automobile production will be 25.225 million units. It is estimated that the annual output value of China's automotive electronics wiring harness products will exceed 50 billion yuan with the price of 2,000 yuan per single wire harness. The development of automotive wiring harness industry is highly dependent on the automobile industry, and most of the brand car manufacturers have their own mature and stable automobile supporting system. In particular, international automobile enterprises represented by German, American and Japanese companies carry out strict assessment and evaluation on parts suppliers. Their long-term high standard requirements for parts make the combination of automotive wiring harness suppliers and automobile enterprises relatively stable. It is difficult to change the traditional supply chain of automobiles. In addition, the formulation of standards in the automobile field is crucial, and standards determine the market. In terms of the domestic market, most of the large self-owned auto manufacturers have local wiring harness factories with stable supporting production, while foreign-invested and joint-venture auto manufacturers have higher requirements for wiring harness. Most of the wiring harness manufacturers selected are wholly owned or joint ventures of international component manufacturers in China.

In recent years, as international automobile manufacturers pay more attention to cost control and the localized purchase of auto parts is increasingly strengthened, a number of excellent autonomous wiring harness enterprises have emerged in China. Through long-term accumulation of product technology and synchronous development experience, these high-quality local enterprises have significantly enhanced their overall strength, and gradually entered the supplier supporting system of international automobile manufacturers with timely and effective service and reliable product quality.

As the new energy vehicle(Electric vehicle)market is an emerging market, no matter international or local manufacturers have too many existing products to promote, so the strength of suppliers' research and development ability will determine their share in the new energy vehicle market. In the process of rapid development of new energy vehicles(EV), wiring harnesses are one of the most important auto parts, mainly including EV car wiring harnesses, BMS wiring harnesses, Energy storage wiring harnesses,etc. as the new energy lithium battery is very unstable, battery management system (BMS) as the core technology plays a pivotal role. The BMS wiring harness is the most important and plays the role of the nerve center. In BMS wiring harness, there are many sensors besides wires. Vehicle batteries are new and cannot be done by traditional automakers (the supply chain system of traditional automakers is difficult to change). However, they have high requirements on wiring harness, which must be short,thin and soft, and must also accept large current, dustproof, waterproof and interferenceproof.

In addition, the suppliers of the early automobile industry chain were unwilling to and did not believe in electric vehicles. Coda, and the earliest electric vehicle manufacturer Fisker, both went out of business successively. Tesla was the third one. Tesla uses Panasonic's 18600 battery. The Model 3 will have 21700 batteries, which are 18% larger size and 70% larger capacity. The car is lighter and faster.

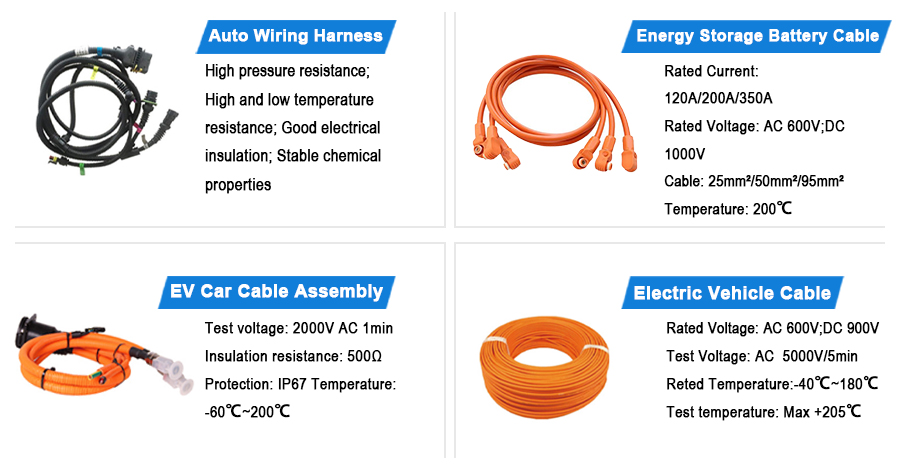

It is bound to form an industry promotion for domestic new energy wiring harness enterprises. The new energy vehicle wiring harness industry is expected to usher in a period of rapid development. When entering the new energy wiring harness industry, we should have some understanding of the related products, which are as follows:

These 5 high voltage wiring harnesses must be know:

High voltage wiring harness is a key connector and cable in electric vehicles in the whole operation of the vehicle, the main hidden dangers affecting the high voltage wiring harness are overheating or combustion, and the harsh environment on the wiring harness and shielding performance, the risk of water and dust, etc. It mainly includes pure electric vehicles, extended-range electric vehicles, hybrid electric vehicles, fuel cell electric vehicles, hydrogen engine vehicles, other new energy vehicles and so on. In new energy vehicles, whether hybrid models or pure electric models, high voltage system as one of the core parts, its importance is self-evident. And the high voltage wire harness as a medium to connect the components of the high voltage system is also a great contribution. Due to the impact of the working environment and safety of the high voltage system, the high voltage wiring harness must improve its own capabilities, such as the following requirements for performance.

Performance of voltage:

The rated voltage is 600VAC/900VDC or 1000VAC/1500VD

Performance of Current:

According to the power flow of the high-voltage system, it is commonly used at 250A, and some high-power motors can be used up to 400A.

Performance of Temperature:

High temperature resistance grade is divided into 125℃, 150℃, 200℃, high temperature conventional selection: 150℃ cable;

Low temperature conventional selection: -40℃ wire.

Performance of shielding:

Shielding high voltage wire can reduce the influence of electromagnetic interference (EMI) and radio interference (RFI) on the vehicle system. The whole high voltage wire harness circuit is shielded.

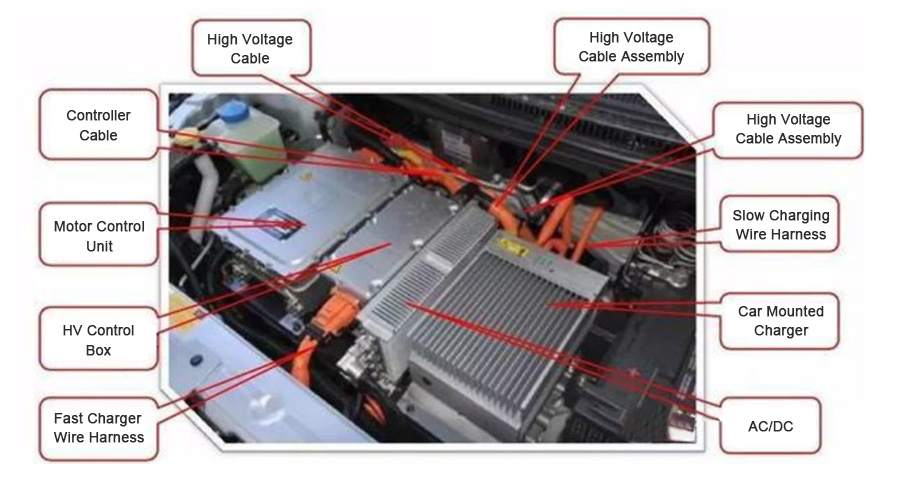

In new energy vehicles (pure electric for example), the high voltage wiring harness can be divided into five parts

1. Power battery high-voltage cable: The cable harness connecting the power battery to the high-voltage box

2. Motor controller cable: the wiring harness connecting the high voltage box to the motor controller

3. Fast charging cable harness: connects the fast charging port to the high voltage box

4. Slow charging wire harness: the wire harness connecting the slow charging port to the vehicle charger

5. Hhigh voltage wiring harness assembly: that is, the wiring harness connecting the high voltage box to the DC/DC, vehicle charger, air conditioner compressor, and air conditioner PTC.

Safety wiring harness in new energy vehicles

In the whole high voltage system wiring harness, in addition to the high voltage wiring harness, there is also a wire harness called safety wire. The wiring harness is a 12V ring wire that passes through each high voltage component. If a safety line breaks somewhere, the data bus diagnostic interface unit J533 (the gateway) gets the information from the relevant control unit and displays the information to the driver through the instrument unit

AICHIE Tech Electronics Co.,Ltd

Email: sales03@aichie.com

Mobile/Whatsapp/WeChat: (86)18027502150

Skype: live:.cid.8643b3df38ff8b5